Grain Separator: Enhancing Efficiency in Agriculture

Agriculture is the backbone of our global food supply, and at the heart of this industry lies a diverse range of crops, from grains like wheat and rice to seeds and pulses. Ensuring the purity and quality of these crops is essential, and that’s where grain separators come into play. In this comprehensive guide, we will explore the fascinating world of grain separators, understanding their importance, how they work, their types, and their impact on the agricultural landscape.

The Significance of Grain Separation

Grain separation is a crucial step in agriculture that involves separating grains from impurities and other unwanted materials. The primary goal is to obtain clean, high-quality grains that can be used for various purposes, including human consumption, animal feed, and seed production.

Importance in Food Production

In the food industry, grain separators are instrumental in producing clean and safe grains for human consumption. Removing contaminants and foreign materials ensures that the end product is of high nutritional value and free from potential hazards.

Seed Quality and Crop Production

For seed production, the quality of grains used for planting is paramount. Grain separators help ensure that seeds are free from debris and have a uniform size, leading to better crop yields and healthier plants.

Livestock and Animal Feed

Grain separation is crucial for producing high-quality animal feed. Clean grains with consistent size and nutritional value are essential for livestock health and productivity.

How Grain Separators Work

Grain separators employ various mechanisms to achieve their goal of separating grains from impurities. Here’s a brief overview of their working principle:

Gravity Separation

Gravity separators use differences in weight and density to separate grains from lighter impurities. As grains fall through an inclined air stream, lighter materials are blown away, leaving the clean grains to fall into a separate collection chamber.

Sieving and Screening

Mechanical separators utilize sieves or screens with different-sized openings to separate grains based on their size. Smaller grains pass through the openings while larger ones are retained.

Magnetic Separation

Magnetic separators use magnets to remove ferrous materials, such as iron and steel, from the grain stream. This method is particularly effective in removing metal contaminants.

Air Aspiration

Air aspiration separators use air currents to lift lighter materials, such as chaff and dust, away from the grains. This leaves the clean grains to fall into a separate container.

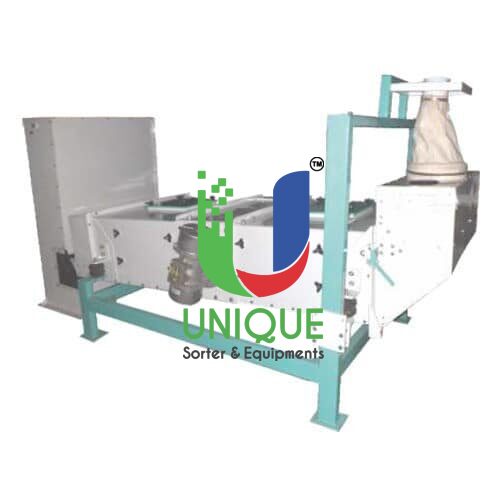

Types of Grain Separators

Grain separators come in various types, each suited to specific applications and processing requirements:

Spiral Separators

Spiral separators use gravity and centrifugal force to separate grains based on their shape and density. They are effective for sorting round grains from non-round materials.

Vibratory Separators

Vibratory separators use vibrations and oscillations to separate grains based on size. They are versatile and can be adjusted for different grain sizes.

Magnetic Separators

As mentioned earlier, magnetic separators use magnets to remove ferrous contaminants from grains. They are commonly used in grain processing plants and mills.

Air Separators

Air separators rely on air currents to separate grains from lighter impurities. They are effective in removing materials like chaff, dust, and husk.

Gravity Tables

Gravity tables use the principle of gravity separation to sort grains based on density. They are particularly useful for separating grains of similar size but different densities.

Advantages of Using Grain Separators

The adoption of grain separators in agriculture brings forth numerous advantages:

Enhanced Product Quality

Paddy separators ensure that the final product is of the highest quality, free from contaminants and impurities that can affect taste, appearance, and safety.

Increased Efficiency

These machines significantly reduce manual labor and processing time, leading to higher productivity and lower production costs.

Improved Crop Yields

Clean and uniform grains obtained through grain separation are vital for achieving optimal crop yields, whether for food production or seed planting.

Preservation of Machinery

By removing foreign materials that can damage machinery and equipment during processing, grain separators contribute to extending the lifespan of agricultural equipment.

Compliance with Quality Standards

Grain separators help farmers and producers meet stringent quality standards and regulations, ensuring that their products are marketable and safe for consumption.

Grain Separation in a Nutshell

In the world of agriculture, grain separators are unsung heroes, quietly working to ensure the purity and quality of our staple crops. Whether it’s ensuring that our daily bread is free from contaminants, optimizing crop yields, or producing high-quality seeds, these machines play a pivotal role in modern agriculture. As technology continues to advance, so too will the efficiency and effectiveness of grain separators, contributing to the sustainability and growth of the agricultural industry.

Innovations in Grain Separation

As technology continues to advance, so does the realm of grain separation. Modern grain separators are equipped with innovative features and technologies that enhance their performance and efficiency.

Optical Sorting

Optical sorters use cameras and sensors to identify and remove even the smallest defects, discolored grains, and foreign materials. This technology can significantly improve the quality of the final product.

Computerized Control Systems

Sophisticated computerized control systems allow operators to fine-tune the separation process, adjusting parameters such as airspeed, vibration intensity, and screen size to achieve the desired results.

Mobile and Portable Units

Mobile grain separators are designed for flexibility and on-the-go use. They can be transported to various locations, making them ideal for seasonal harvesting or processing at different farms.

Internet of Things (IoT) Integration

IoT-enabled grain separators can be monitored and controlled remotely. This feature allows operators to optimize the separation process in real-time and receive maintenance alerts, reducing downtime.

Energy Efficiency

Modern separators are designed with energy efficiency in mind, reducing power consumption and environmental impact. This not only lowers operational costs but also aligns with sustainable practices.

Future Trends in Grain Separation

The future of grain separation holds exciting possibilities:

Artificial Intelligence (AI)

AI-powered grain separators can learn and adapt to different grain types and quality standards. They can make real-time decisions about separation parameters, leading to even more precise results.

Sustainability

There is a growing emphasis on sustainability in agriculture. Future grain separators may incorporate eco-friendly materials, energy-efficient designs, and processes that minimize water usage.

Blockchain Traceability

Blockchain technology may be integrated into grain separation processes, allowing for the seamless tracking of grain origins, quality, and safety throughout the supply chain.

Customization

Grain separators of the future may offer extensive customization options, allowing operators to tailor the separation process to the specific needs of their crops and markets.

Conclusion

In conclusion, as we wrap up our journey through the world of grain separators, it becomes evident that these remarkable machines are the unsung heroes of agriculture, shaping the quality and efficiency of our food production. From separating grains with precision to embracing cutting-edge technologies, grain separators have evolved to meet the ever-growing demands of modern agriculture.

But let’s not forget that these separators are just one piece of the puzzle in the broader context of agriculture. The grains they process are the very foundation of our diets, deeply intertwined with cultural traditions and culinary heritage. Much like our exploration of “Exploring the Rich Culture of Rice in India,” we recognize that grains have a profound cultural significance that transcends their utilitarian role.

As we delve into the technical intricacies of grain separation, it’s essential to remember that these processes enable us to preserve and celebrate the rich traditions associated with grains like rice. They ensure that the grains we consume reflect not only our cultural heritage but also the innovation and efficiency that define modern agriculture.

To continue your exploration of related topics, consider visiting the “Color Sorter Wikipedia” page to dive deeper into the technology that enhances grain separation. Additionally, for those interested in pulse processing, our guide on “Dal Sorter Machine” sheds light on the specialized equipment that refines pulses, a dietary staple in many cultures.

In the end, our understanding of agriculture is enriched by recognizing the intricate interplay between technology, culture, and tradition. Grain separators are but one chapter in this fascinating story, a story that continues to evolve and shape the way we nourish ourselves and honor our cultural roots.

Get A Quote

Related Post

Discover the art of precision with our color sorter: revolutionizing sorting processes with unparalleled accuracy and efficiency.

Elite Corn Color Sorter Machine

Elite Corn Color Sorter Machine, powered by the revolutionary Jarvis system and Smart vision technology.

Elite Coffee Bean Sorter Machine

Elite Coffee Bean Sorter Machine, a pinnacle of precision and efficiency in the world of coffee sorting technology.

Elite Spices Color Sorter Machine

Revolutionize your spice sorting processes with unmatched efficiency and accuracy of Elite spice sorter.