Technical Guidelines for Manufacturing Blended Fortified Rice

Welcome to our blog post dedicated to unraveling the intricacies of the manufacturing process behind blended fortified rice. In this chapter, we delve into the fundamental steps required for producing Fortified Rice Kernels (FRK) and Fortified Rice (FR), shedding light on the roles and responsibilities entrusted to the production unit staff.

The objectives outlined in this chapter are twofold: firstly, to acquaint production staff with the essential procedures involved in the production of Fortified Rice, and secondly, to familiarize employees at State/District Food Departments and rice mills with their respective roles and responsibilities. Join us as we embark on a journey to demystify the production process and empower stakeholders with the knowledge necessary to ensure the seamless production and distribution of this vital nutritional resource.

What is Fortified Rice Kernel (FRK)?

Fortified Rice Kernel (FRK) is a revolutionary nutritional solution crafted through a meticulous process involving rice flour, essential vitamins, and minerals, all combined using advanced hot extrusion technology. This process unfolds seamlessly through five key steps:

Mixing of raw material:

The journey of FRK begins with the careful blending of rice flour, vitamins, minerals, and specified additives. These components are harmoniously mixed in precise proportions, ensuring the creation of a balanced nutritional profile. The mixture is then hydrated using water treated by Reverse Osmosis to achieve the prescribed moisture content.

Extrusion:

The uniformly hydrated mixture undergoes a transformative process as it is passed through a twin-screw extruder. Here, under controlled conditions, the mixture takes on the form of tiny pellets, closely resembling traditional rice grains. This step is crucial in shaping the FRK and ensuring its uniformity and quality.

Drying:

Once extruded, the nascent FRK proceeds to the drying stage. This critical step involves slow drying at low temperatures, meticulously executed to reduce moisture levels to a safe threshold while preserving the integrity and nutritional value of the product. High-quality FRK is the result of careful attention to detail during this pivotal phase.

Storage:

Post-drying, the finished FRK is stored in an intermediary storage bin, where it awaits packaging. This intermediate storage ensures optimal conditions for the FRK, maintaining its quality and freshness until it is ready for distribution.

Packaging:

The culmination of the FRK production process involves meticulous packaging designed to safeguard its nutritional integrity. FRK is carefully sealed in special two-layer bags, featuring an inner poly lining crafted from premium food-grade material. These innovative bags, available in varying sizes to meet diverse needs, provide protection against moisture and pests, ensuring that the FRK reaches consumers in pristine condition.

Through these intricately choreographed steps, fortified rice kernels (FRK) emerge as a potent nutritional resource, poised to combat deficiencies and enhance health outcomes worldwide.

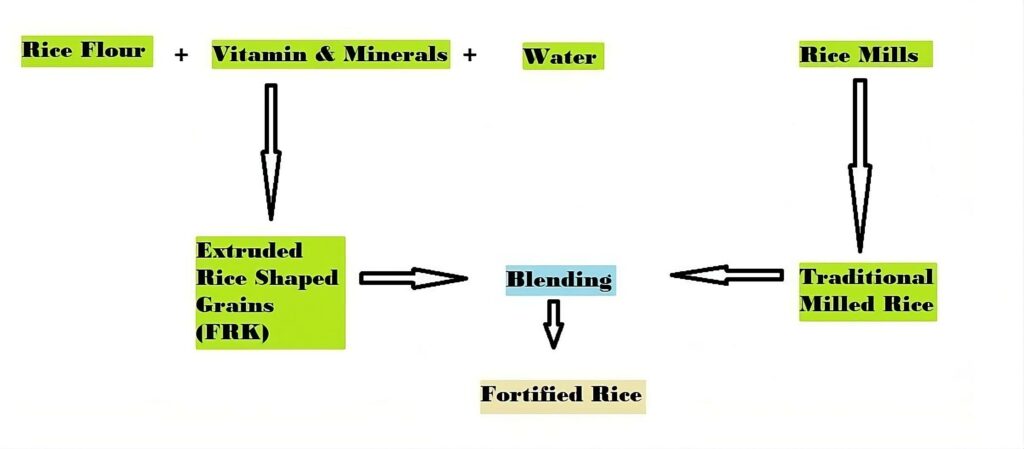

Process of rice fortification

The process of rice fortification is a meticulously orchestrated series of steps aimed at enriching rice with essential vitamins and minerals, ensuring optimal nutritional value and quality. Here’s a comprehensive breakdown of the key elements involved:

Sourcing/Producing of Fortified Rice Kernels (FRK):

The journey begins with the sourcing or production of Fortified Rice Kernels (FRK), the foundation of fortified rice. These kernels are meticulously crafted using rice flour, vitamins, minerals, and specified additives.

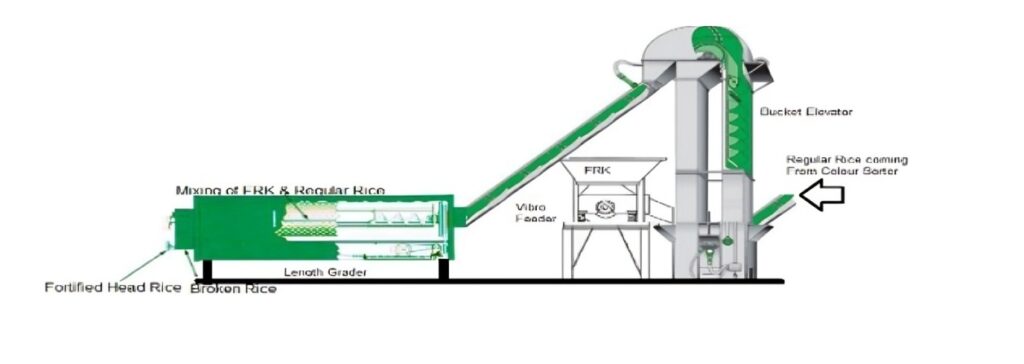

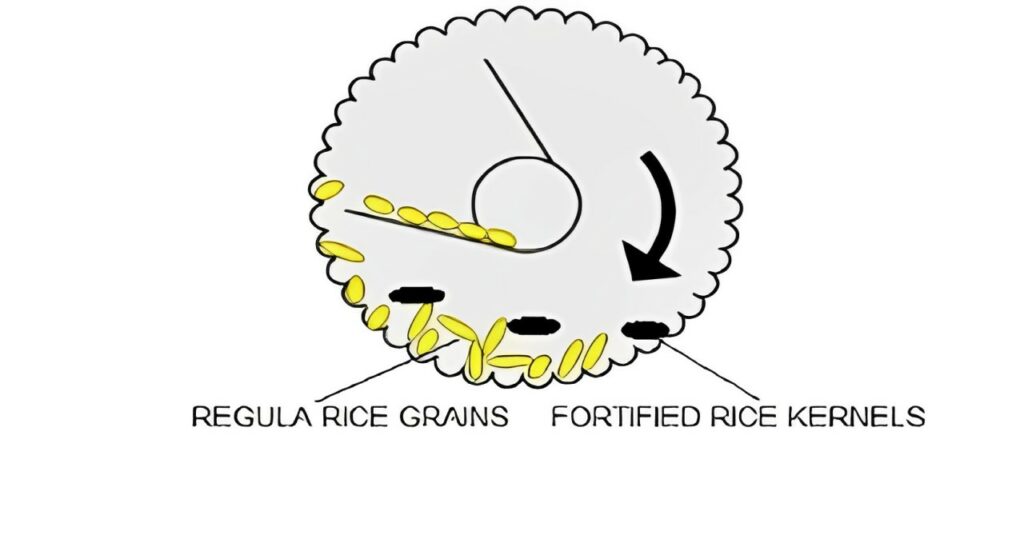

Blending FRK with Raw Milled Rice:

The next step involves blending the FRK with raw milled rice, typically in a ratio of 1:100 (FRK:Raw Milled Rice). This blending process ensures uniform distribution of essential nutrients throughout the rice.

Quality Assurance and Control:

Quality assurance and control measures are paramount throughout the production process. Stringent protocols are in place to maintain the highest standards of quality and safety, from raw material selection to final packaging.

Packaging:

Once fortified, the rice undergoes meticulous packaging to preserve its nutritional integrity and freshness. Specialized two-layer bags, designed to protect against moisture and pests, are utilized to ensure that the fortified rice reaches consumers in optimal condition.

Fortification Technologies:

Several technologies can be employed for rice fortification, with extrusion emerging as the most robust and widely used method. This process involves the addition of vitamins and minerals to rice flour, followed by extrusion to produce Fortified Rice Kernels (FRK). Extrusion ensures minimal nutrient loss during subsequent processing and cooking.

Raw Material Selection:

The selection of raw materials is a critical determinant of fortified rice quality. Ingredients such as rice flour, food-grade vitamin and mineral premixes, emulsifiers, acid regulators, and potable water must meet stringent specifications to ensure the desired nutritional profile and cooking quality.

Role and Responsibilities of Plant Manager:

The plant manager plays a pivotal role in overseeing fortified rice production, adhering to established guidelines, and ensuring operational excellence. Responsibilities include machine operations, quality control, decision-making on raw materials, and compliance with regulatory standards.

In essence, the process of rice fortification embodies a commitment to nutritional excellence, guided by stringent quality standards and meticulous attention to detail at every stage of production.

Choice of blending machine

When it comes to the choice of blending machine for the production of fortified rice, several factors come into play, including the capacity of blending, type of pre-blending system, and the overall efficiency of the blending process. Here’s an in-depth exploration of the different types of blending machines available:

Stand-alone Blender:

Ideal for small-scale operations, stand-alone blenders offer a cost-effective semi-automatic blending solution. With a capacity ranging from 400-2000 kg on a daily basis, these systems feature stainless steel mixing drums and operate similarly to concrete mixers. They are easy to operate, requiring minimal training, and complete blending within 5 minutes.

Batch Blender:

Suited for medium-capacity environments, batch blenders like the Forsberg® Batch mixer are capable of producing fortified rice in small batches ranging from 100 kg to 500 kg per hour. These paddle-type mixers ensure uniform blending of rice and FRK within a closed chamber, offering fully automatic operation with limited manual intervention.

Continuous Blender:

To meet high demand, continuous blending systems like the plow shear mixer offer extensive capacity and homogeneous blending. These systems feature rotating shafts with plow assemblies and are capable of handling large quantities of rice and FRK with high efficiency. Continuous blending ensures consistent quality and uniform distribution of nutrients.

Selection Criteria and Testing:

Blenders are selected based on various parameters such as accuracy of mixing index and efficiency. Tests are conducted to standardize RPM, flow rate, and capacity, ensuring optimal performance and blending homogeneity. Among the tested blenders, the zig-zag blending system has emerged as the most efficient, offering the highest mixing index for fortified rice blending. Modifications are made as necessary to further enhance performance and efficiency.

Efficiency of various blending machines

| Particulars | Zigzag Blender | Drum Blender | Rice Length Grader |

| Type | Continuous | Continuous | Continuous |

| Application | Rice Milling | Rice Milling | Rice Milling |

| Capacity | 5 MT/ hr | 1-10 MT/hr | 1-1.5 MT/hr |

| Ratio | 100 to 1 | 100 to 1 | 100 to 1 |

| Mixing index (Blender Efficiency) | 0.94-0.96 | 0.99855 | 0.70-0.80 |

| Blending System Efficiency | 0.846-0.864 | 0.89865 | 0.63-0.72 |

| Power Consumption (Blender) | 3 kW | 3 kW | 1 kW |

| Cost of Operation | In the rice mill setting, operational costs are minimized as the blender is installed after final sorting, ensuring efficient operation whenever needed. | In rice mills, operating costs are minimized with the installation of this blender post-final sorting, ensuring cost-effective operation whenever needed. | The primary role of the length grader is to separate broken rice from head rice during the grading process. However, if the length grader is used for blending fortified rice, an additional blending process is required after grading. This results in increased operational costs as the grading system cannot simultaneously produce fortified rice, necessitating separate operation and full engagement of the rice milling system. |

| Compatibility | Manual/ Semi Auto/Fully auto rice mill with color sorter | Manual/ Semi Auto/ Fully auto rice mill color sorter | In rice mills without a color sorter, both manual and semi-automatic operations are common. Here, the length grader is typically utilized before the color sorter. When the rice passes through the color sorter, the Fortified Rice Kernels (FRK) are separated from the fortified rice. |

| Possibility to control the flow control | The system autonomously manages rice flow and subsequent blending, ensuring self-sustainability. | The system maintains self-sustainability by autonomously regulating the flow of rice and facilitating subsequent blending processes. | To ensure consistent rice flow, it’s imperative to incorporate a flow balancer and rice hopper before the elevator. Additionally, calibration of the vibratory feeder is necessary to match the rice flow ratio of 100:1. |

| Limitation | Not applicable, as the buffer hopper has been installed to regulate rice flow. | Not applicable, as the buffer hopper has been installed to regulate rice flow. | Ensuring uniform feeding of both Regular Rice and FRK presents a significant challenge. Any plant breakdown requires readjustment of feeding, potentially impacting the blending index. |

Prioritizing Safety and Hygiene: Ensuring Quality Standards in Blended Fortified Rice Manufacturing

Ensuring the safety and hygiene of blended fortified rice involves a multifaceted approach encompassing various factors and practices. It is crucial to prevent product adulteration and implement measures to mitigate potential hazards that could compromise consumer health. This includes maintaining cleanliness and sanitation in processing environments and equipment, alongside adherence to stringent personnel practices, pest control measures, and warehousing protocols.

A comprehensive sanitation program and Hazard Analysis and Critical Control Points (HACCP) system are essential components of ensuring food safety. Good Manufacturing Practices (GMPs) serve as guidelines to ensure compliance with government regulations, emphasizing the biological, chemical, and physical safety of finished products.

Key objectives of food safety include educating plant staff on maintaining hygiene and safety standards, understanding potential hazards, and implementing precautionary measures. Common food preparation practices contributing to foodborne illnesses include improper holding temperatures, poor personal hygiene, inadequate cooking, contaminated equipment, and unsafe food sources.

Food contamination can arise from microbiological, chemical, or physical hazards. Cross-contamination, a leading cause of food poisoning, occurs when harmful germs spread from one source to another. Preventative measures such as good personal hygiene, proper handling, preparation, and storage of food are crucial in mitigating foodborne illnesses.

The World Health Organization (WHO) outlines five key principles of food hygiene: preventing contamination, separating raw and cooked foods, cooking foods thoroughly, storing food at appropriate temperatures, and using safe water.

In India, the Food Safety and Standards Authority of India (FSSAI) regulates food safety standards, requiring adherence to GMP/GHP principles and HACCP protocols in fortified rice production. Despite fortified rice products being low moisture and stable, stringent manufacturing processes are necessary to ensure compliance with regulatory standards and uphold consumer safety.

Quality Assurance and Quality Control

Quality assurance and quality control are paramount in ensuring the integrity and nutritional efficacy of fortified rice, a vital component in addressing malnutrition worldwide. Fortified rice, or FRK, undergoes rigorous scrutiny at various stages of production, storage, and distribution to uphold its quality standards and ensure its nutritional value. This introduction delves into the comprehensive framework encompassing quality management practices, food safety protocols, and external testing mechanisms crucial for maintaining the excellence of fortified rice throughout the supply chain.

The quality management of FRK begins with meticulous sourcing from state-empaneled manufacturers, who adhere to stringent guidelines outlined by regulatory bodies such as the Food Safety and Standards Authority of India (FSSAI). Prior to dispatch, manufacturers must furnish a Certificate of Analysis (COA) for both the FRK and the premix used in its production, affirming compliance with prescribed nutrient levels and FSSAI specifications. External NABL accredited laboratories conduct essential tests to validate micronutrient content, ensuring alignment with regulatory standards while preserving the visual and textural attributes synonymous with regular rice.

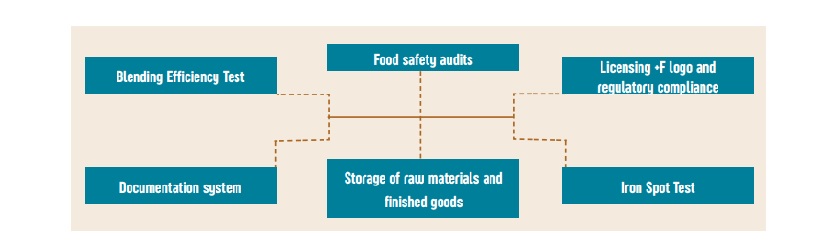

At the milling stage, stringent protocols govern the handling and blending of FRK with common rice (CMR) to maintain uniformity and stability. Quality checks encompass visual inspections, moisture content assessments, and the implementation of Good Manufacturing Practices (GMP) and Good Hygiene Practices (GHP) to mitigate contamination risks. Blending Efficiency Tests (BET) and Iron Spot Tests further verify the homogeneity and nutritional integrity of the final product.

Continuous monitoring and documentation are integral components of the quality assurance process, necessitating meticulous record-keeping and adherence to regulatory requirements. Internal audits and surprise inspections bolster accountability and reinforce adherence to established protocols. Additionally, external testing through NABL accredited laboratories provides independent verification of nutrient content and microbial safety, bolstering consumer confidence and regulatory compliance.

Packaging and stenciling of fortified rice bags

Packaging and stenciling of fortified rice bags play a crucial role in ensuring proper identification, preservation, and consumer awareness regarding the fortified nature of the rice. As per the FSSAI Packaging and Labelling Guidelines, specific clauses pertaining to packaging and stenciling are integrated into milling agreements between State Food Departments and rice millers. These clauses are meticulously designed to adhere to regulatory standards and promote consumer confidence in the fortified rice supply chain.

- Consideration of Fortificant and Shelf Life: The packaging of fortified rice must be designed to accommodate the nature of the fortificant added and its impact on the shelf life of the product. This ensures that the nutritional integrity of the fortified rice is preserved throughout its storage and distribution.

- Clear Identification of Fortification: Each package of fortified rice must prominently display the words “Fortified with (name of the fortificant)” along with the +F logo, as specified in Schedule-II of the regulations. Additionally, a tagline such as “Sampoorna Poshan Swasth Jeevan” may accompany the logo, further emphasizing the nutritional benefits of the fortified rice.

- Compliance with Packaging and Labelling Regulations: The provisions outlined in the Food Safety and Standards (Packaging and Labelling) Regulations, 2011, are applicable to fortified foods, ensuring that packaging materials and labeling practices adhere to established safety and quality standards.

- Health Advisory for Specific Conditions: Packages containing fortified rice fortified with iron must include a statement advising individuals with Thalassemia to consume the product under medical supervision. This ensures appropriate consumption recommendations for individuals with specific health conditions.

- Permission for Nutrition Claims: Manufacturers and packers of fortified rice who comply with regulatory requirements are permitted to make nutrition claims in accordance with the Food Safety and Standards (Packaging and Labelling) Regulations, 2011. This allows for transparent communication of the nutritional benefits of fortified rice to consumers.

References:

- FRK Operational Guidelines 25.07.2019

- IS 17780 OF 2021 (Specifications FR)

- IS 17781 OF 2021 (Specifications FRK Premix)

- IS 17782 OF 2021 (Specifications FRK)

- SoP for FRK and FR 15.03.2022

- FSSAI Instructions 23.06.2022

- Operational guidelines dated 13-12-2023 and corrigendum on Quality Control for FRK and FR

- Foodsuppb.gov.in

- Tulchinsky TH. Micronutrient Deficiency Conditions: Global Health Issues. Public Health Rev. 2010;32(1):243-255. doi: 10.1007/BF03391600.

- International Institute for Population Sciences (IIPS) and ICF. 2017. National Family Health Survey (NFHS-4), 2015-16: India. Mumbai: IIPS.

Get A Quote

Related Post

Discover the art of precision with our color sorter: revolutionizing sorting processes with unparalleled accuracy and efficiency.

Elite Corn Color Sorter Machine

Elite Corn Color Sorter Machine, powered by the revolutionary Jarvis system and Smart vision technology.

Elite Coffee Bean Sorter Machine

Elite Coffee Bean Sorter Machine, a pinnacle of precision and efficiency in the world of coffee sorting technology.

Elite Spices Color Sorter Machine

Revolutionize your spice sorting processes with unmatched efficiency and accuracy of Elite spice sorter.